what's next?

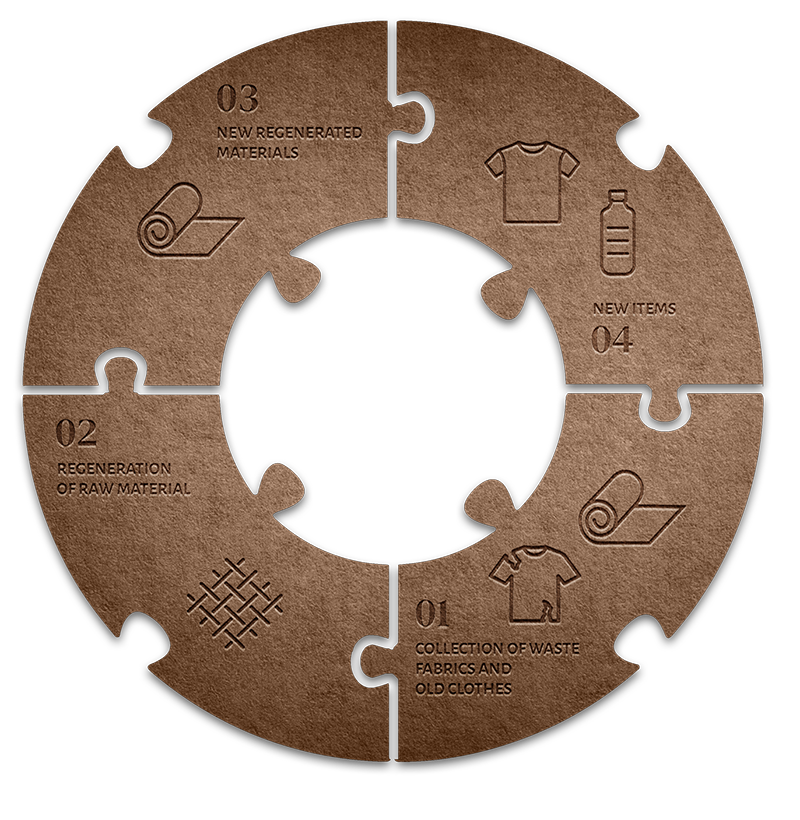

create value, not waste

We encourage you to give back to us your post-consumer Monobi garments in order to guarantee them a second life chance.

Our partner

Beredo

By partnering with Beredo, we ensure that returned garments are transformed into new products or materials, reducing waste and conserving resources.

(WOOL, CASHMERE and more)

REGENERATION OF ANIMAL AND NOBLE FIBERS

The regeneration of wool and noble fibers, especially cashmere, is a typical practice of the textile district where Monobi was born.

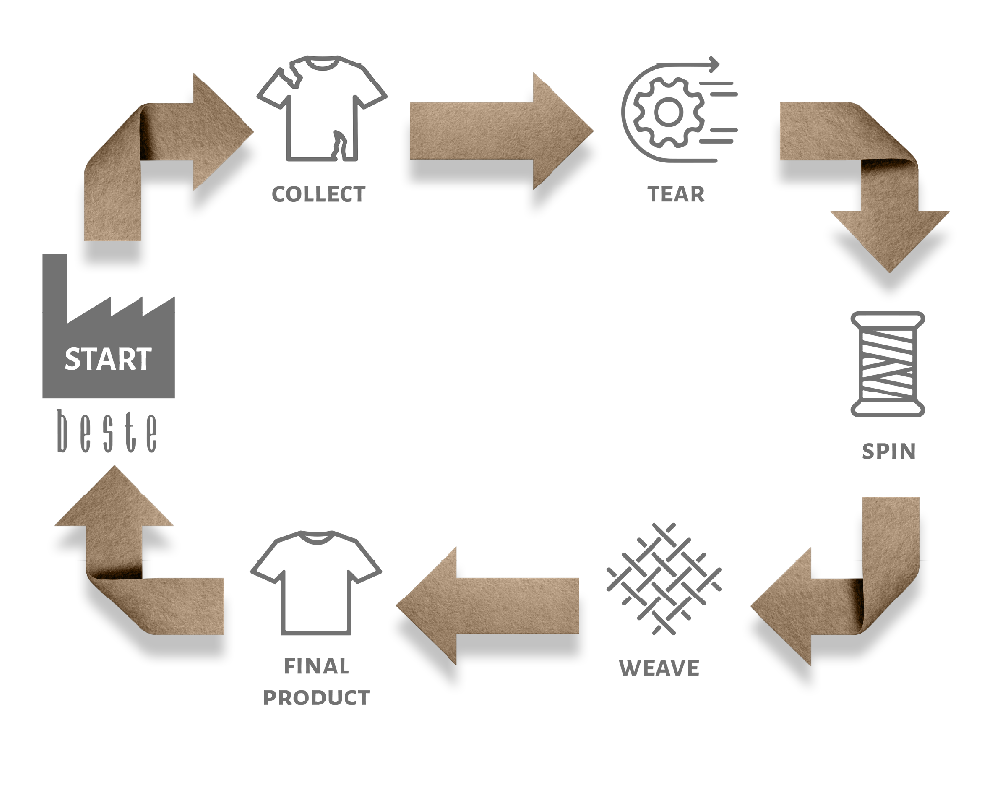

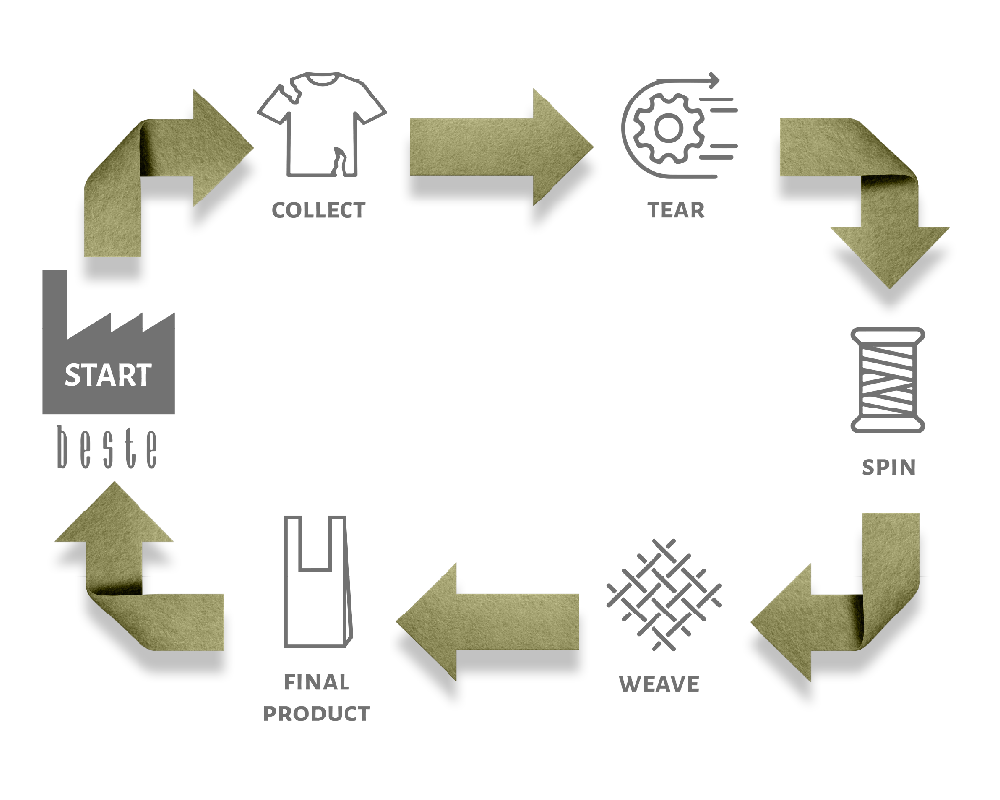

The recycling process starts with the collection of production waste and post-consumer garments, which are sorted by color. Then, the yarn structure is demolished and transformed into reusable fiber, ready for a new life cycle.

COTTON REGENERATION

A first particular shredding is carried out to preserve the length of the fiber. Then it is enhanced by mixing recycled fibers with virgin organic cotton in order to increase the resistance. This regenerative process allows resources saving too: the creation of a recycled cotton t-shirt, in fact, only requires 30 liters of water, against the 2700 liters required for a virgin cotton t-shirt.

Even the denim can be completely recycled: starting from pre and post-consumer garments and following the cotton regenerative process, we are able to generate new denim materials with amazing blue shades due to the indigo special feature.

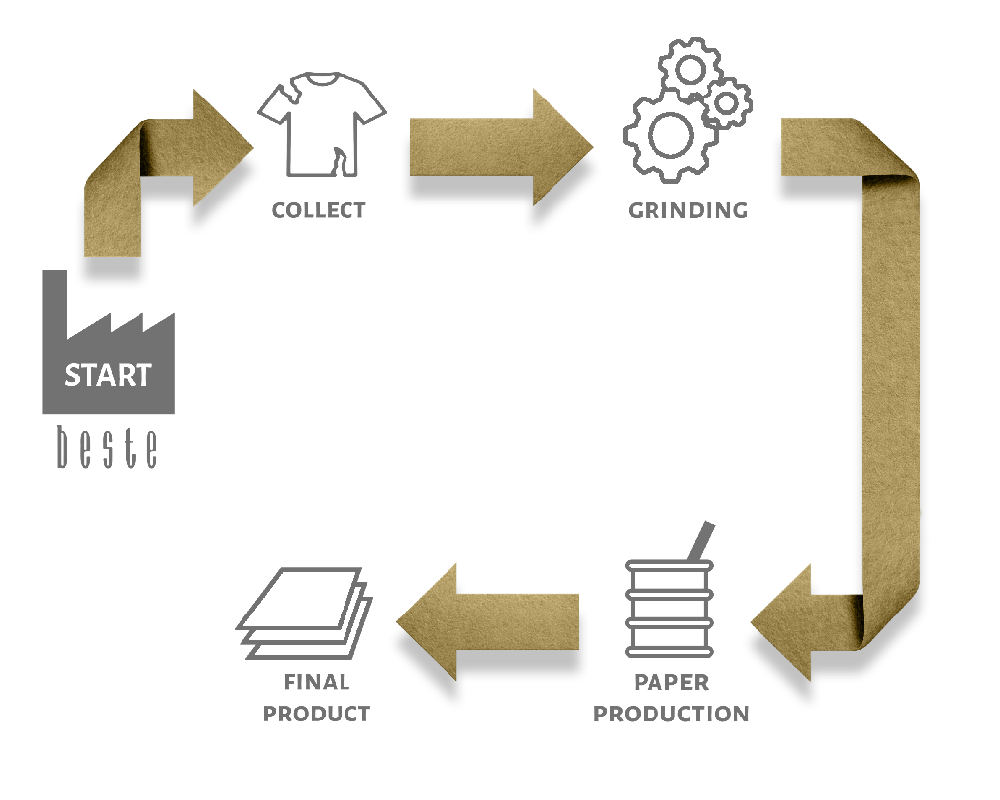

RECYCLED PAPER

Traditionally, paper is obtained from cellulosic textile rags, frayed and soaked in water. Thanks to innovative tools, Beredo is able to produce recycled paper-made materials coming not only from cellulose, but also from animal fibers and leather scraps.

The result is a wide range of recycled materials for the paper industry: paper, caskets, boxes, customizable shopping bags, made with waste materials up to 50%.

(“ROSSINO”)

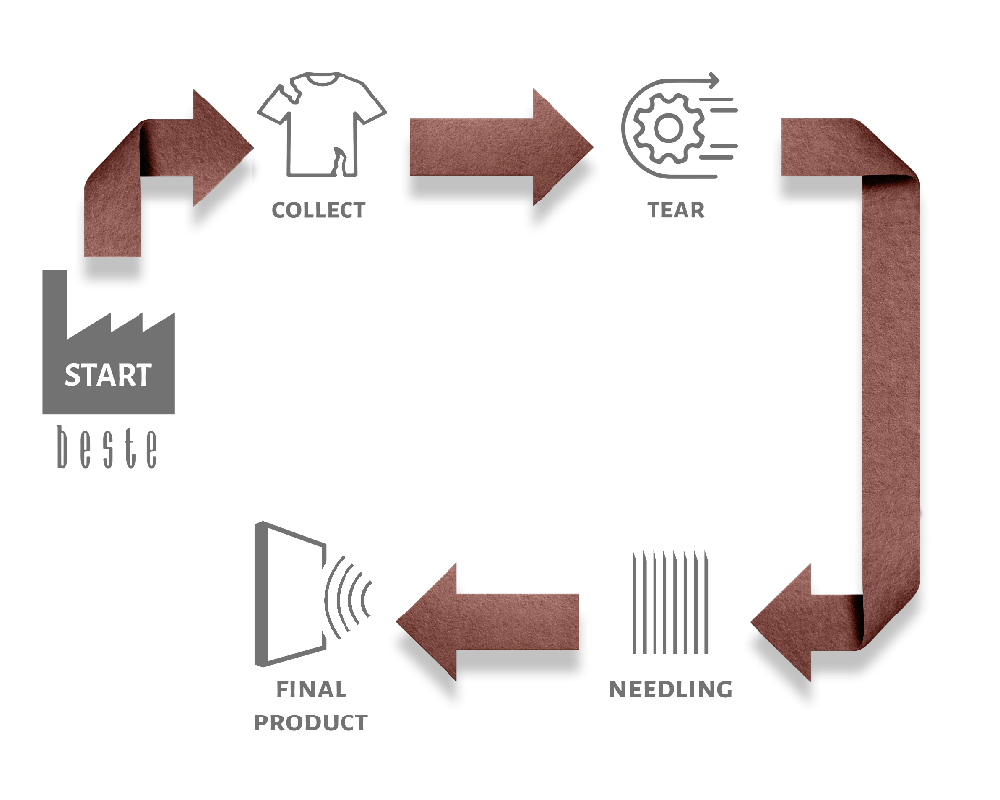

MIXED MATERIALS

The otherwise unrecoverable mixed fiber waste is transformed into thermo- acoustic panels used in the automotive industry for internal insulation and seat padding. Heat and pressure are the tools to create this kind of material that comes in the form of blocks.

Thanks to this practice, all waste that would otherwise be burned into incinerators can now be recycled and have a new life into the automotive industry.

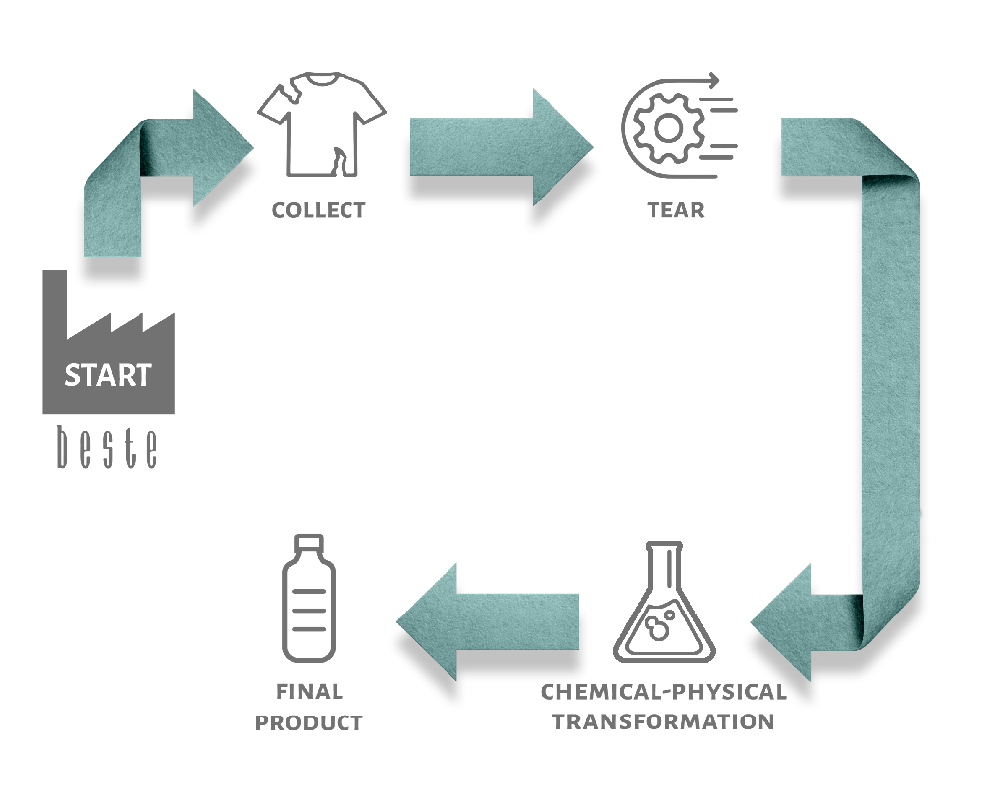

(Polyester and Polyamide)

SYNTHETIC FIBERS

Our polyamide fiber waste is recovered and regenerated through a complex both chemical and physical process based on pulverization. The new material is exactly the same as its petroleum-based counterpart, except for the fact that it is entirely made from waste, without added virgin raw materials.

Thank to this innovative process patented by Beredo, the waste nylon is regenerated into recycled polyamide yarns to produce new textile fabrics.