TRACK BACK TO MOVE FORWARD

A transparent company has nothing to hide. We trace every process to provide customers and consumers with an immediate and fully traceable understanding of our supply chain activities. We guarantee transparency and responsibility throughout the entire production process, from the raw material to the finished product.

Track your future

Following the NFC label tag applied on every MONOBI garment, any person will be able to access the DPP (Digital Product Passport) and discover the whole product journey, as well as information about durability and reparability, recycling and reusability. The exploration of MONOBI fully traceable production chain - will be accessible from any mobile device.

traceability in your pocket

RAW MATERIALS

Here the first phase of the journey of our garment takes place: the raw material. For the construction of our garments we use GOTS (Global Organic Textile Standard) certified cotton, obtained from the leading company in the sector ICA Yarns. We also use RWS (Responsible Wool Standard) certified wool obtained from Tianyu Wool, a very important Chinese company. Finally we use SFA (Sustainable Fiber Alliance) certified Mongolian cashmere supplied to us by the King Deer company.

SPINNING

For the cotton spinning process, our company relies on Ramco, a leading company in the Indian textile sector. For the spinning of the wool we rely on two Tuscan companies, FIL.G.A and Filatura Santa Giusta. For the cashmere spinning we rely on King Deer, a leading company on the Chinese market.

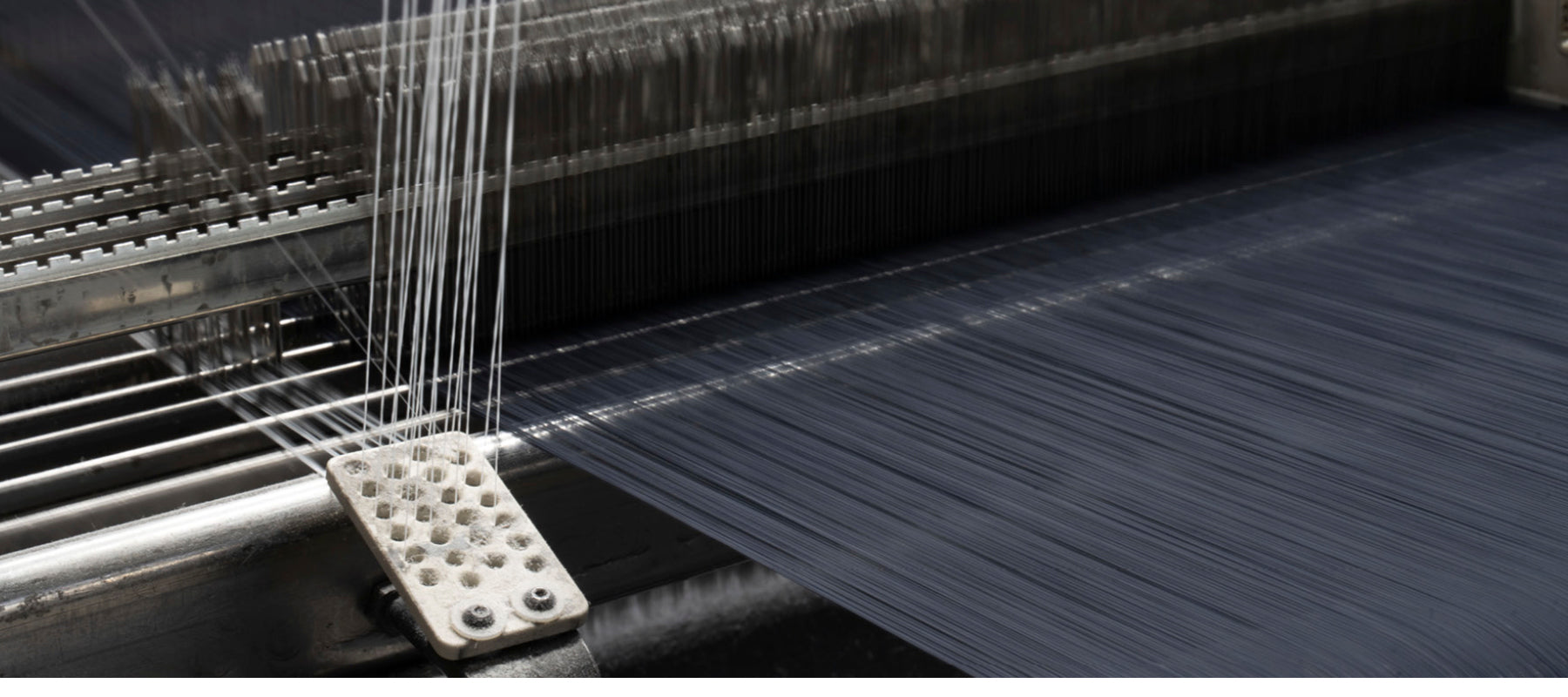

WEAVING AND KNITTING

For the weaving process we rely on 3 established companies: Dinamiche Tessili Piantini, Lanificio Arca and King Deer. The first two located in Tuscany, while the last located in Inner Mongolia. For the knitting processes we rely on two Italian companies: Milmax and New Esse Maglieria.

DYEING AND FINISHING

The dyeing and finishing process is carried out by large companies in the Italian territory, 100% Made In Italy. The companies are specifically: RTP based near Prato, Cambi Luigi near Prato and Beste also in Prato.